We also wanted these glasses to be defined by PLANBLUE – our path to a holistically sustainable company. In their search for a sustainable production facility for glass here in the region, our colleagues from environmental management came across the small manufactory Glasdesign in Bern. At the end of June, we picked up the 300 ordered glasses in the company’s own plug-in hybrid automobile in PLANBLUE design (charged with solar power, naturally) and spoke with plant manager Daniel Egger on site, who also showed us the various steps required to create the finished PLANBLUE glass.

Mr. Egger, when was the company founded?

Mr. Egger, when was the company founded?

Glasdesign was founded in 1997 and was the first glass upcycling company in Switzerland. The idea to reuse and process disposable bottles came from a similar project in Finland.

You are a trained cabinet maker. How did you end up at Glasdesign and what fascinates you about glass upcycling?

In 2003, I wanted to do an internship in a field that combines craftsmanship and social aspects. Due to a lack of internship positions in wood workshops, I was referred to a glass upcycling company and was offered a permanent position as a craftsman after my internship. This, I followed up with an apprenticeship as an employment coach at Glasdesign, where I have been plant manager since 2010. I still find the process of creation from the bottle to the decorated glass object exciting after all these years.

What in particular do you like about the Glasdesign concept? How many employees do you have and how did they end up at your company?

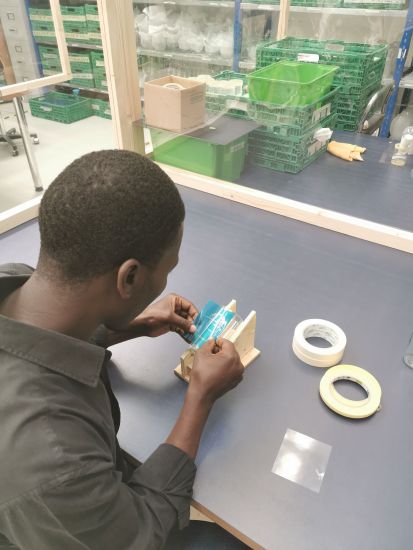

Since 2001, Glasdesign has been a project of the Directorate of Education, Social Welfare and Sport of the City of Berne that provides jobs for people  receiving social welfare benefits. Only people who have been out of the primary job market for a long time are hired. At the moment, we have 30 employees aged 25-60 years with different origins, life situations, and backgrounds. The special thing about the Glasdesign concept is that we not only manufacture numerous products, but we also combine craftsmanship with professional and social integration of the long-term unemployed.

receiving social welfare benefits. Only people who have been out of the primary job market for a long time are hired. At the moment, we have 30 employees aged 25-60 years with different origins, life situations, and backgrounds. The special thing about the Glasdesign concept is that we not only manufacture numerous products, but we also combine craftsmanship with professional and social integration of the long-term unemployed.

What are the goals of the project? To what extent do the acquired skills and social competences help the employees in their further professional life?

A job at Glasdesign means a meaningful occupation with a daily structure for job seekers, offering them the opportunity to expand their technical and social skills. Thanks to this learning and work opportunity, they improve their chances on the job market. They are given process support in their professional and/or social integration.

What does a typical day of work look like at your company? What tasks do the employees carry out?

In the morning, the department managers distribute the workload. Afterwards, employees go to the respective workstations in our production hall. We have currently divided the group into two due to the distancing requirements: One group in the morning, the next in the afternoon. Working with us is not job-specific and the production process offers many learning opportunities. The tasks include: washing, cutting, grinding, polishing, decorating, sandblasting, setting up. In addition, there are the shipping, warehousing, and transport departments.

What exactly is produced at Glasdesign and where do you get the material from?

What exactly is produced at Glasdesign and where do you get the material from?

Our core business is developing, manufacturing and selling upcycling products made from waste glass. We make many objects for everyday use, such as drinking glasses, vases, bowls, table lamps, etc., and offer various sizes, colors, and shapes. In addition to our standard products, we also make custom products or one-off pieces on request for private individuals or, as now with the RONAL GROUP order, for companies.

We get the old bottles from restaurants, bars and beverage dealers, but also from private individuals. To avoid having completely different “starting materials,” it is important for us to be able to obtain waste glass from the same suppliers over a longer period of time.

Who do you supply with your products?

We supply resellers and private customers; we also sell directly from our shop in Bern and via our online shop. In addition, we offer workshops teaching others how to process used glass. These events are suitable for clubs, company departments, or other groups.

Are you planning to expand, broaden the range of products and services on offer in the future, possibly creating more jobs?

In terms of our organizational structure, it’s out of our hands whether we can create more jobs. But we try to constantly improve and adapt our work processes to the people working for us. In addition, we would like to further expand the area of customer orders. I hope that we can continue to fulfil our dual mission in the future and offer meaningful employment to people with difficult access to the job market.

Check out the gallery to see how our PLANBLUE glasses were created!