PRODUCTION

MELTING PROCESS

TOP QUALITY ALUMINUM FOR A SOUND BASE

We obtain 100% of our aluminum from members of the Aluminum Stewardship Initiative (ASI), which guarantees adherence to stringent sustainability criteria, in addition to premium-quality aluminum. The aluminum ingots are scanned with a barcode to ensure their traceability.

The aluminum alloy is heated to approximately 760 degrees. The melted aluminum is then taken out of the furnace and the temperature measured, before being cleaned of impurities and undergoing further processing. It is possible to improve the properties of the material with additives, thereby ensuring optimum quality.

A sample is taken from every transport batch and checked for compliance with the specifications using density measurement and spectral analysis.

CASTING

BOTTOM UP

The wheels are manufactured using low-pressure die casting (LPDC). The molten mass is conveyed into a steel mold via a riser pipe through gas pressurization of the holding furnace.

This is followed by visual inspection for quality control purposes. Casting burrs are removed and the wheel measured.

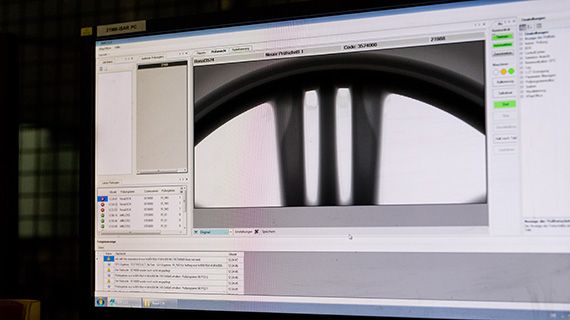

X-RAYS

DETAILED EXAMINATION

Every wheel is scrutinized 100% by automatic X-ray machines. A special program identifies the design and inspects wheel quality according to the precise specifications of the customer.