ALWAYS ON THE LOOKOUT FOR POTENTIAL FOR IMPROVEMENT

The RONAL GROUP has been creating a carbon footprint report for the Group and its individual plants since the 2017/18 financial year.

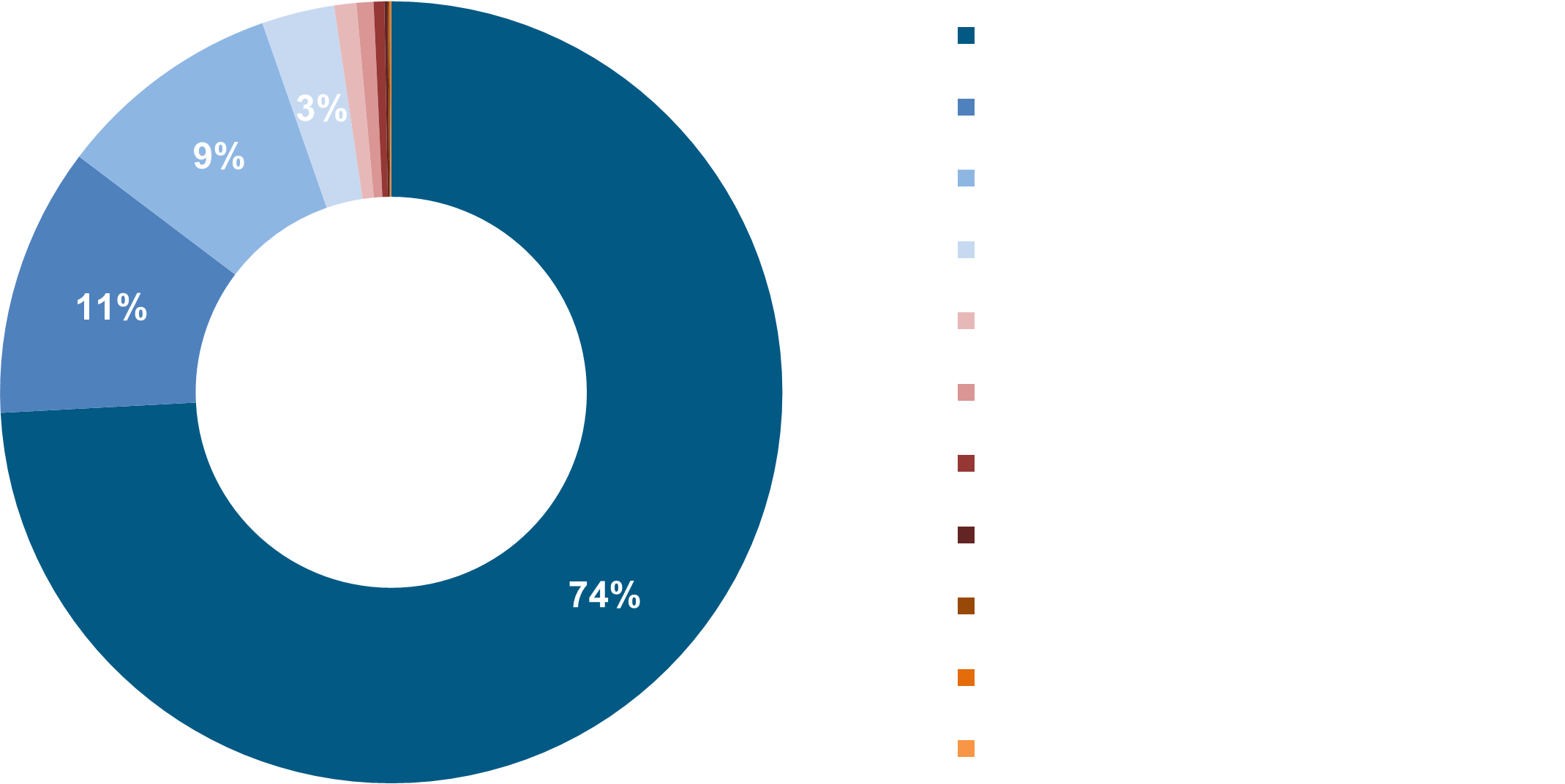

Our most important resource is aluminum. Its production accounts for 74% of our carbon emissions, the most significant percentage in total. Other substantial sources of emissions, accounting for 20% of the total balance, are electricity consumption and gas consumption for process heat.

There is one question we keep asking ourselves: Where do we have potential for improvement? Our focus is partly on reducing aluminum consumption in smelting and casting, and on the sustainable procurement of primary aluminum on the other. Another area of focus is purchasing renewable electricity with a certificate of origin or, where possible, producing electricity in-house with photovoltaic systems or combined heat and power plants.

There is one question we keep asking ourselves: Where do we have potential for improvement? Our focus is partly on reducing aluminum consumption in smelting and casting, and on the sustainable procurement of primary aluminum on the other. Another area of focus is purchasing renewable electricity with a certificate of origin or, where possible, producing electricity in-house with photovoltaic systems or combined heat and power plants.

Our energy and environmental policy reflects our company’s intentions and alignment with regard to energy and environmental performance, as well as our philosophy.