The requirements of the automotive industry and end users with regard to our wheels are stringent. Wheels that have to withstand all conceivable stresses on the road – and sometimes even off-road or on the racetrack – consequently undergo rigorous testing as prototypes at RONAL’s own development lab. We use the latest test facilities to reproduce all situations that might occur in road traffic and check our wheels for function and service life. They are only released for production once all tests have been completed successfully.

We also distinguish between aftermarket testing and OEM testing in this field. Aftermarket testing is described in detail in the German Road Traffic Licensing Regulations (StVZO) and is validated by the TÜV organization. The scope and duration depend on the extent of the variants (vehicles/rim offsets/pitch circles). Release may be completed by documentation such as KBA certificates, ECE approval or special country-based specifications (e.g. Japan/USA/Asia).

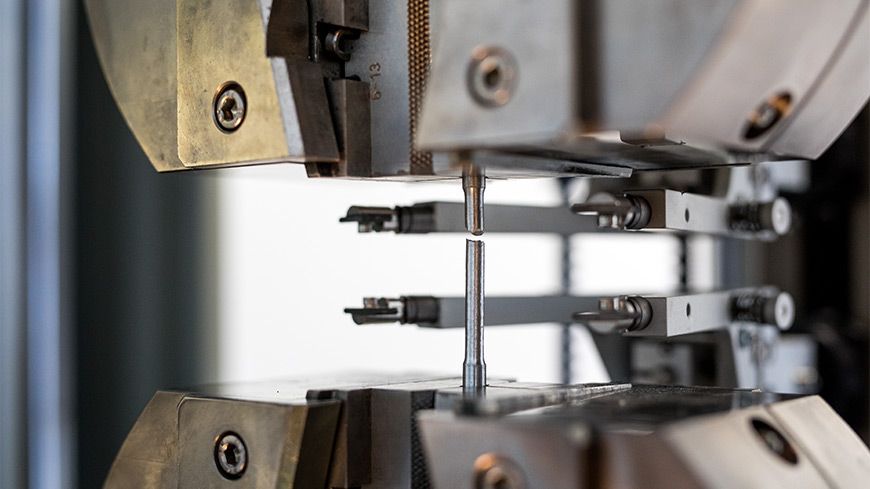

The test requirements of car manufacturers vary widely in terms of test values and the types and duration of testing – sometimes specialized test equipment is even required here. The tests performed by the RONAL GROUP and the results are then accepted and adopted by our customers. There is a trend towards international requirements, e.g. from Brazil, China or Korea, etc., which prolong the release process. The tests carried out always cover fatigue strength and possible misuse, and additionally focus on different temperature ranges and application areas. Should initial parts fail such strength testing, the wheel can be reinforced at critical points by removing material from the mold.